Grinding balls inspection

Forged grinding balls are widely used in Gold mining or Copper mining

which will follow the strict quality control system

1.Raw material of steel balls Pre-production checks

Steel Bars ( Diameter, Length of Cut Bars , Heating number signature )

Equipment includes Air Hammer , Forging Hammer, Cooling time and Quenching time and etc.

Temperature control- Quenching Start temperature and quenching end temperature ( Produce 10 grinding balls

then stop production and test the samples )

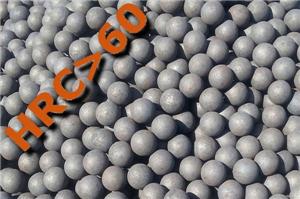

2. Grinding balls Surface Hardness Measurement

Balls 1-----Balls 10 HRC recordings

Surface hardness Target

3. Grinding balls Core Hardness Test . Cutting 2 balls for further inspection

4. Heating treatment before Packing ( Record heating batch , temperature )

5. Final Hardness Test before dispatch , Marking the hardness result on the steel drum of grinding balls